Box Beam Production Line

Introduction

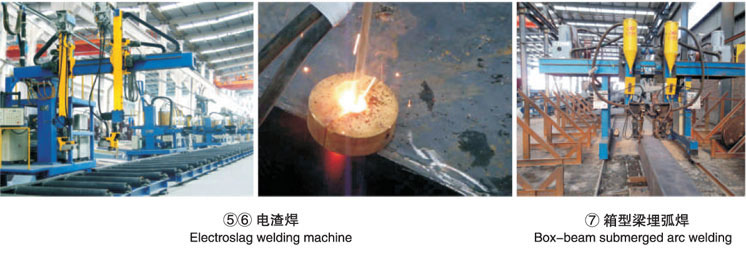

Box beam production line can complete the operations of loading material, cutting, assembling, backing welding, electroslag welding and edge milling. This box beam welding line has advantages of low investment, small occupation area, high automation and high efficiency. It can be divided into single machine production line and automatic product line. The line is made of cutting machine, assembly machine, cantilever electroslag welder, automatic gantry welding machine, end face milling machine, edge milling machine and roller

Advantages

1. Our box beam production line has practical and smooth process layout. It can realize operations of manual welding, back welding, end tab and riser cutting and welding seam inspection.

2. Driven by electric motor, the travel wheels beneath the movable 180°hydraulic overturning rack enables the rack to move. This helps box beam welding line overcome the impact of work piece to the rack and greatly enhances the stability of work-piece overturning.

3. The box beam production line adopts pre-cut hole method for electroslag welding, which eliminates welding defects brought by cutting fluid and iron scraps during drilling process.

4. Box beam flips 90°to both sides. This ensures all manual welding can be in the down-hand welding position and avoids inverted welding caused by single direction 90°overturning.

5. With double arc double wire welding technology and welding seam tracking device, the box beam production line effectively improves welding efficiency, guarantee welding quality and avoid inaccurate positioning of pneumatic tracking system.

Classification of Box Beam Production Line

1. Box Beam Assembly Machine

The assembly machine is structured by conveying roller, web plate centring clamping mechanism, hydraulic system and electronic control system. It is operated manually. It moves work piece while it itself remains unmoved.

2. Automatic Box Beam Welding Machine

2. Automatic Box Beam Welding Machine

It is particularly designed for box beam welding. It adopts gantry structure, bilateral drive and frequency conversion stepless regulation. Welding tracking employs mechanical guide roller which uses pneumatic control. To improve welding efficiency of welding leg, the double arc double wire welding is employed. The flux protective device reduces flux scattering.

3. Automatic Box Beam Electroslag Welder

3. Automatic Box Beam Electroslag Welder

Automatic box beam electroslag welder mainly consists of traveling bench, vertical lifting mechanism and horizontal moving mechanism. Nozzle-fusion electroslag welding system can be provided.

Parameters of Box Beam Production Line

| Length (mm) | 4000-15000 |

| Section Size (mm²) | 300 * 300 -1200 *1200 |

| Thickness of Plate (mm) | 20-80 |

| Weight (Kg) | ≤ 20000 |

Package and Shipment

1. Foam paper, steel shelf and wooden case are often used to pack box beam welding line equipment.

2. Ocean shipping is only available

Payment

L/C and T/T are both accepted types of payment for box beam production line.

TallKee MATERIAL has become a professional box beam production line supplier through five years of development. Our main products include CNC cutting machine, H beam product line, straightening machine, welding machine, welding turning roll, welding positioner, welding manipulator, milling machine and flux recovery equipment. All the products have entered such foreign markets as the USA, Canada, Russia, Italy, Australia, New Zealand, Japan, India, Singapore, Brazil, Indonesia, Malaysia, UAE, etc. For details, welcome to visit our website or contact us directly.

- Self-Aligning Welding Rotator This series of self-aligning welding rotator is suitable for automatic welding of circumferential and longitudinal seam of metal cylinder when matched with YZH welding machine. On the other hand, this welding turning roll can also provide help to manual welding. Besides, it helps to test and assembly cylinders. It drives clamp holder to automatically modulate barycentre by taking advantage of welding piece weight. Thus ...

English

English Español

Español Português

Português Русский

Русский