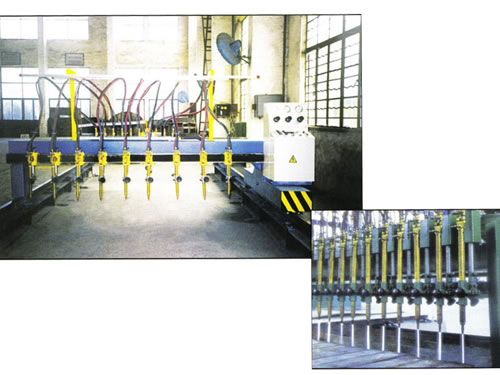

Multi-Head Strip Cutting Machine

Introduction

Multi-head strip cutting machine is a high efficient gas flame cutting equipment that uses oxygen and acetylene as cutting fuel. It is installed with one set of flame cutting torches on the front, which is used for horizontal or diagonal cutting. On the back side, it has two sets of flame cutting torques used for longitudinal straight cutting. H beam strip cutting machinery can provide various cutting system for client selection. It can cut both strip and abnormally shaped pieces.

Features

1. Multi-head strip cutting machine employs imported AC motor, helical gear reducer and precision gear rack.

2. The cutting speed can be adjusted through imported AC inverter.

3. H beam strip cutting machinery is designed with a gas source control box, conveniently adjusting every gas pressure.

4. Main pipe and every control valve are imported products to ensure reliable and safe operation.

5. Horizontal cutting torch pipeline layout is safe and beautiful with adopting imported towing chain.

Advantages

1. Multi-head strip cutting machine uses PANASONIC high precision servo drivers.

2. Imported pipes are applied to lengthen service life.

3. CNC cutting torches are fixed by high precision lead screw and roller liner guide, making sure that they are on the same vertical line.

4. Portal frame girder of H beam strip cutting machinery is bended and tempering processed, preventing deformation.

5 With steel welded frame and double axis guide rail, multi-head strip cutting machine overmatches other similar products in many aspects. Various performances reach or exceed standard.

Parameters of Multi-Head Strip Cutting Machine

| Specification | YZCG-4000 | YZCG-5000 | YZCG-6000 | |||

| Track Range (mm) | 4000 | 5000 | 6000 | |||

| Effective Cutting Width (mm) | 3200 | 3700 | 4200 | |||

| Min. Cutting Width (mm) | CNC | 230 | 230 | 230 | ||

| Strip | 80 | 80 | 80 | |||

| Plate Thickness (mm) | 6-100 | 6-100 | 6-100 | |||

| Cutting Speed (m/min) | Frequency Control | 0.05-2 | 0.05-2 | 0.05-2 | ||

| Servo Drive | 0.05-6 | 0.05-6 | 0.05-6 | |||

| Max. Return Speed (mm/min) | Frequency Control | 2000 | 2000 | 2000 | ||

| Servo Drive | 6000 | 6000 | 6000 | |||

| Cutting Precision (mm) | ± 0.5/1000 | |||||

| Roughness of Cut Surface | Ra12.5 | |||||

| Repeated Accuracy | ±0.5 | |||||

| Main Pipe | Oxygen | P=1MPa | ||||

| Acetylene | P=0.1MPa | |||||

| Voltage | AC220V±10% | |||||

| Frequency | 50HZ | |||||

| Total Power of Gas Cutting Machine (Kw) | 1.5 | |||||

Maintenance

1. Regularly clean every part, including components in CNC control box, power source box etc.

2. Regularly oil and clean gear, gear box, rack, rail.

3. Regularly remove Scraps filter to clean.

TallKee MATERIAL is a professional manufacturer of auto welding equipment (including multi-head strip cutting machine) and H- beam production equipment. Our products have been certificates of CE and Product Patent. To better serve our clients, the company provides a series of customer services, including technical consulting, technical solution, free hoisting, field instruction about installation and debugging, training, and so on. Moreover, customization and OEM are also available. For details, do not hesitate to call us.

- H Beam Assembling MachineH beam assembly machine is generally applied in the spot welding and assembling of the cut plates. The flange and web plate of main frame respectively has two sets of centring clamping devices which are driven by hydraulic cylinder. The hydraulic cylinder drives rack to move gear which drives other transmission mechanism. This H beam automatic assembling machine is composed of main frame, flange plate, web plate ...

English

English Español

Español Português

Português Русский

Русский