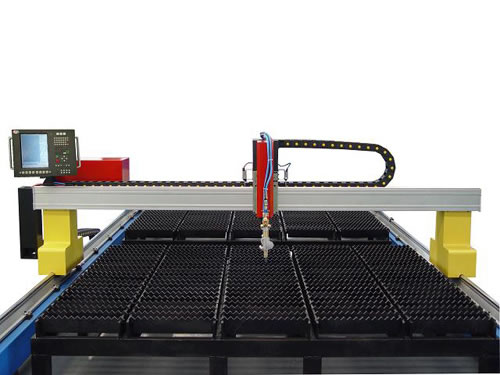

CNC Plasma Cutting Machine

Introduction

The CNC plasma cutting machine manufactured by us is broadly used in such industries as chemical, automobile, general engineering machinery, etc. This CNC plasma cutter can be furnished with plasma power supply of HYPERTHERM, THERMADYNE and KJELLBERG. Besides, domestic plasma power is also available. It has several types for client selection, such as dry type, half-dry, underwater and fine plasma. Presently, our CNC plasma cutting machine wins wide application in multiple types of mechanical parts with the advantage of simple operation and high precision.

Features

1. The gas circuit of CNC plasma cutting machine adopts imported pipes which enjoy long service life.

2. It is equipped with a remote operation box, simplifying operation and reducing labor cost.

3. The CNC plasma cutter employs PANASONIC high precision servo driver

4. Plasma cutting has ability to cut all kinds of sheet metal. Besides, it is quick and efficient.

5. The cutting system of CNC plasma cutting machine is featured by stable performance and easy maintenance. It uses the system of BeJing Start Company.

6. CNC torches are positioned by precise lead screw and roller liner guideway, ensuring the torches are on the same vertical line. And cutting accuracy is guaranteed, too.

Parameters about CNC Plasma Cutting Machine

| Specification | YZCN-4000A | YZCN-5000A | YZCN-6000A | |

| Track Span (mm) | 4000 | 5000 | 6000 | |

| Effective Cutting Width (mm) | 3200 | 3700 | 4200 | |

| Vertical Stroke of Cutting Torch | 170 | |||

| Plate Thickness (mm) | 6-100 | 6-100 | 6-100 | |

| Flame Cutting Speed (mm/min.) | 50-1000 | |||

| Plasma Cutting Speed (mm/min) | 350-6000 | |||

| Quick Return Speed (mm/min) | 6000 | |||

| Flame Cutting Width (mm) | 6-100 (Single Shot), Piecing Thickness ≤ 80 | |||

| Plasma Cutting Width (mm) | Recommendation can be offered according to customers’ requirements. | |||

| Flame Cutting Material | Soft Steel | |||

| Plasma Cutting Material | Soft Steel, Aluminum, Stainless Steel | |||

| Power Supply | One-phase AC220V, 50HZ, 2KVA | |||

| Total Power of CNC Plasma Cutter (Kw) | 1.5 | |||

American HYPERTHERM

Brand |

Model |

Ma. Piercing Cut Thickness (mm) |

Max Cut Out Thickness (mm) |

Recommended Cut Thickness (mm) |

Input Power (Kw) |

||||||||

| MS | SS | Aluminum | MS | SS | Aluminum | MS | SS | Aluminum | |||||

American HYPERTHERM |

Powermax45 | 10 | 10 | 10 | 25 | 19 | 10 | 6 | 6 | 6 | 5.95 | ||

| Powermax65 | 12 | 12 | 12 | 25 | 20 | 12 | 8 | 8 | 8 | 9 | |||

| Powermax85 | 16 | 16 | 16 | 30 | 25 | 16 | 10 | 10 | 10 | 12.2 | |||

| Powermax105 | 22 | 19 | 19 | 38 | 32 | 19 | 14 | 12 | 12 | 16 | |||

| Powermax200 | 32 | 25 | 32 | 75 | 75 | 32 | 25 | 25 | 25 | 30 | |||

| HSD130 | 25 | 20 | 20 | 38 | 25 | 20 | 16 | 16 | 16 | 19.5 | |||

| HPR130XD | 32 | 20 | 20 | 38 | 25 | 20 | 16 | 16 | 16 | 19.5 | |||

| HPR260XD | 38 | 32 | 25 | 64 | 50 | 25 | 32 | 32 | 32 | 45.5 | |||

| HPR400XD | 50 | 45 | 75 |

45 | 80 | 80 | 45 | 38 | 38 | 38 | 80 | ||

| HPR800XD | 50 | 45 | 100 |

75 | 80 | 160 | 75 | 38 | 75 | 75 | 160 | ||

Maintenance and Repair

1. Regularly clean every part of CNC plasma cutting machine, including components in CNC control box, power source box, etc.

2. Regularly oil and clean gear, gear box, rack and rail of CNC plasma cutter.

3. Regularly remove scraps filter for cleaning.

TallKee MATERIAL specializes in making and supplying CNC plasma cutting machine and other equipment. The company has constantly introduced foreign advanced technology and machines. All our products are exported to the USA, Canada, Russia, Italy, Australia, New Zealand, Japan, India, Brazil, Singapore, Malaysia, Indonesia, Iran, UAE, etc. For about 10 years, Hongjie has been putting clients at the first place and pursuing to satisfy our clients. If you have interest in CNC plasma cutting machine, please contact us.

- CNC Oxy-Fuel Flame Cutting MachineOur CNC oxy-fuel cutting machine works to cut metal materials with fuel gas or gasoline plus oxygen. Its minimum cutting width is 230 mm. The plate thickness ranges from 6 mm to 100mm. The cutting speed of our gas cutting machine is 0.05 to 6m per minute and the max. return speed turns to be 6000 mm/min. With this cutter, the roughness ...

English

English Español

Español Português

Português Русский

Русский